General Characteristics

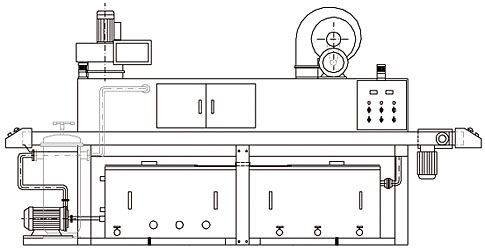

TUNNEL VARIETY: In order to clean,

rinse and dry in very short cycles that can-if wanted- become

part of the continuous line of production. Any of the steps

can be skipped according to the client’s need. TUNNEL VARIETY: In order to clean,

rinse and dry in very short cycles that can-if wanted- become

part of the continuous line of production. Any of the steps

can be skipped according to the client’s need.

BATCH VARIETY: In batches, with the same characteristics,

washing, rinsing and drying are done in short cycles.

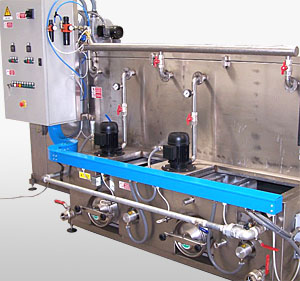

They are made of a stainless steel pleated sheets on which a

wire mesh or stainless steel chain conveyor belt is found. There

are lateral rails made of the same material. Inspection lids

on the top and side are thermally isolated, as are the spare

water tank, the pump, speed reducer, water filter, regenerative

turbine and electric switchboard. They are made of a stainless steel pleated sheets on which a

wire mesh or stainless steel chain conveyor belt is found. There

are lateral rails made of the same material. Inspection lids

on the top and side are thermally isolated, as are the spare

water tank, the pump, speed reducer, water filter, regenerative

turbine and electric switchboard.

The size of the tunnel is determined by the client’s type

of production. Standard sprinklers are used but they are  specific

for the needs of the parts to be treated. The supporting structure

is made of stainless steel tubes and can be removed for maintenance

purposes. The conveyor belt zone has areas that drain into a

collecting tank that is oriented towards the drainage system

to favor the gathering of water in the recycling tank. specific

for the needs of the parts to be treated. The supporting structure

is made of stainless steel tubes and can be removed for maintenance

purposes. The conveyor belt zone has areas that drain into a

collecting tank that is oriented towards the drainage system

to favor the gathering of water in the recycling tank.

FILLING

AND DRAINING: Filling is carried out using a solenoid valve

with electronically controlled maximum and minimum levels. Drainage

is done through a spherical valve.

HEATING: Water is heated using shielded stainless steel

resistors, located in the compensation tank. The heads of the

resistors are covered by a stainless steel protection box. The

temperature is digitally controlled. HEATING: Water is heated using shielded stainless steel

resistors, located in the compensation tank. The heads of the

resistors are covered by a stainless steel protection box. The

temperature is digitally controlled.

SPRAY: On the top, a removable lid allows clear view

of a dismountable container to which the sprinklers are connected.

MAXIMUM-MINIMUM LIQUID LEVEL SENSOR: It is located inside

the compensation tank and using a double float system, it can

send the information to a solid interphase located on the switchboard

and from there to the solenoid valve.

SOLIDS IN SUSPENSION: These are removed using a filter.

The cleaning fluid circulates thanks to a centrifugal pump adequate

in flow capacity and pressure according to the job to be done.

GENERATION AND TRANSMISSION OF SPRINKLER FLOW CAPACITY:

The size of the compensation tank is determined by the flow

capacity. The pump will then take the liquid from there and

will send it through the sprinklers and into the tunnel according

to the custom made design.

HOT-AIR

DRYING: The size of

the drying tunnel is determined according to the client’s

needs. It is made of stainless steel and the conveyor belt area

has drainage into a collecting tray that has a flexible pipe

leading to the water tank. It has double walls and is thermally

isolated by a ceramic blanket. HOT-AIR

DRYING: The size of

the drying tunnel is determined according to the client’s

needs. It is made of stainless steel and the conveyor belt area

has drainage into a collecting tray that has a flexible pipe

leading to the water tank. It has double walls and is thermally

isolated by a ceramic blanket.

PRELIMINARY DRYING: This is carried

out by a medium to high flow of air produced by turbines directed

by air flow direction flaps towards the parts to be dried.

HEATING: This is done by a centrifugal

fan connected to heaters that are connected in turn to a tunnel

type air flow direction flap that we manufacture. Thus, the

air is directed towards the parts that are to be dried. The

temperature is controlled by a sensor.

TRANSPORTING THE PARTS: The parts are transported by

a wire mesh or stainless steel chain conveyor belt with lateral

rails also made of the same material. It is connected to a speed

reducer that provides the adequate ratios and power. All along

the belt there is a removable stainless steel rail.

CONTROL PANEL: The control panel is located in a box

attached to the device. The switchboard is manufactured

according to ISO norms and works with 24V. The switches

include an on /off switch for the pump, the conveyor belt control

switch (on/off and speed control) thermostat and liquid level

indicator lights. |